Properly selected and maintained control valves increase eficiency, safety, profitability, and ecology. The Control Valve Handbook has been a primary reference since its first printing in …

Valve sizes are small to large including pressure classes of 900 through 2500 (PN 160 to PN 400). Ideal for solutions requiring high pressure, high-pressure drops, high Cv, noise …

nding quality standards. WALWORTH relies on its broad experience in supplying valves to the petrochemical, oil & gas, petroleum, power generation, pulp and paper, cryogenic and …

Properly selected and maintained control valves increase efficiency, safe-ty, profitability, and ecology. The Control Valve Handbook has been a primary reference since its first printing in …

The seat-leakage criteria — no visible leakage for forged steel and 2ml/hour/inch of nominal valve size for cast steel — are stricter than the allowed leakage rate of MSS SP-61, which is …

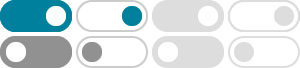

To size a control valve we need to know how much fluid can pass through the control valve. It is important to know what the flow capacity will be at different percent open as well as at different …

The primary purpose of a pressure or vacuum relief valve is to protect life and property by venting process fluid from an overpressurized vessel or adding fluid (such as air) to prevent formation …